100% PURE TALALAY LATEX MATTRESSES

100% PURE TALALAY LATEX

MATTRESSES

| Local Factory | Local Stores | Local Delivery & Set-Up | Removal of Old Bed |

|

1035 E. Camelback Rd., Phoenix 800-733-1818 WHAT DOES IS ALL MEAN . . . FACTORY DIRECT?

PLEASE VISIT OUR PHOENIX AZ FACTORY SHOWROOM & SAVE UP TO 50% OFF |

.jpg)

HAND MADE ONE AT A TIME

WE MAKE, SELL, DELIVER & GUARANTEE

AMERICA'S BEST BUILT LATEX MATTRESSES

|

907 Hollywood Way, Burbank 800-233-7382 1035 E. Camelback Rd., Phoenix800-733-1818Open Mon-Sat 10-5, Sun 12-4 SERVING ALL AREAS |

||||||||||||||||||||

|

32-STEPS TO |

|||||||||||||||||||||

|

Latex starts life out as a seed Originally native to the Amazon Rainforest (now grown in Temperate Climates in Southeast Asia) |

||||||||||||||||||||

| 1. The Seed | |||||||||||||||||||||

|

|

||||||||||||||||||||

| 2. The Tree | |||||||||||||||||||||

The Seed grows up into the Heavea brasilliensis tree where the Latex is drawn from the tree (just like maple syrup) |

|

||||||||||||||||||||

| 3. Latex | |||||||||||||||||||||

|

|

|||||||||||||||||||||

|

It is then imported into the USA by Talalay Global, CT The Liquid latex is first mixed in a temperature controlled, stainless steel tank to eliminate impurities and to create a pure substance. |

||||||||||||||||||||

| 4. Mix | |||||||||||||||||||||

|

The batter is transferred to the pressroom where it is whipped into

a froth and injected into an aluminum picore mold. The pins create the unique aerated cell structure of our latex.  The mold is sealed and a vacuum is pulled to extract air and completely feill the mold cavity with foam. |

|

||||||||||||||||||||

| 5. Pour | |||||||||||||||||||||

|

The batter is frozen to a temperature of 20 degrees. Freezing is unique to the Talalaly process to prevent particaled from setting, exuring a consisten cell structure. |

||||||||||||||||||||

| 6. Freeze | |||||||||||||||||||||

|

CO2 is added to whip the recipe into a frothy state. Temperatures exceeding 200 F degrees are applied to cure the recipe as it is baked into a solid state. |

|

||||||||||||||||||||

| 7. Heat | |||||||||||||||||||||

|

The solid latex is cooled and removed from the mold. |

||||||||||||||||||||

| 8. Remove | |||||||||||||||||||||

|

The latex mattress core is removed from the mold and placed on a conveyer belt that brings it through a five-stage fresh water washer, which removes latex proteins, residual soaps and curing agents. The multi-stage fresh water rinse is also unique to the Talalay process. |

|

||||||||||||||||||||

| 9. Wash | |||||||||||||||||||||

|

The mattress is transported to a two-lane dryer, which completes the curing process and removed residual moisture. |

||||||||||||||||||||

| 10. Dry | |||||||||||||||||||||

EVERY mattress undergoes a nine-point firmness consistency test and infrared technology scan to ensure they meet our stringent quality standards |

|

||||||||||||||||||||

| 11. Test | |||||||||||||||||||||

.jpg) RATED 9 SEPARATE AREAS |

Each Talalay Mattress Core has its own Date Stamp, Serial Number and Rated in 9 Separate Areas (The sticker is on each core) |

||||||||||||||||||||

| 12. Rate | |||||||||||||||||||||

|

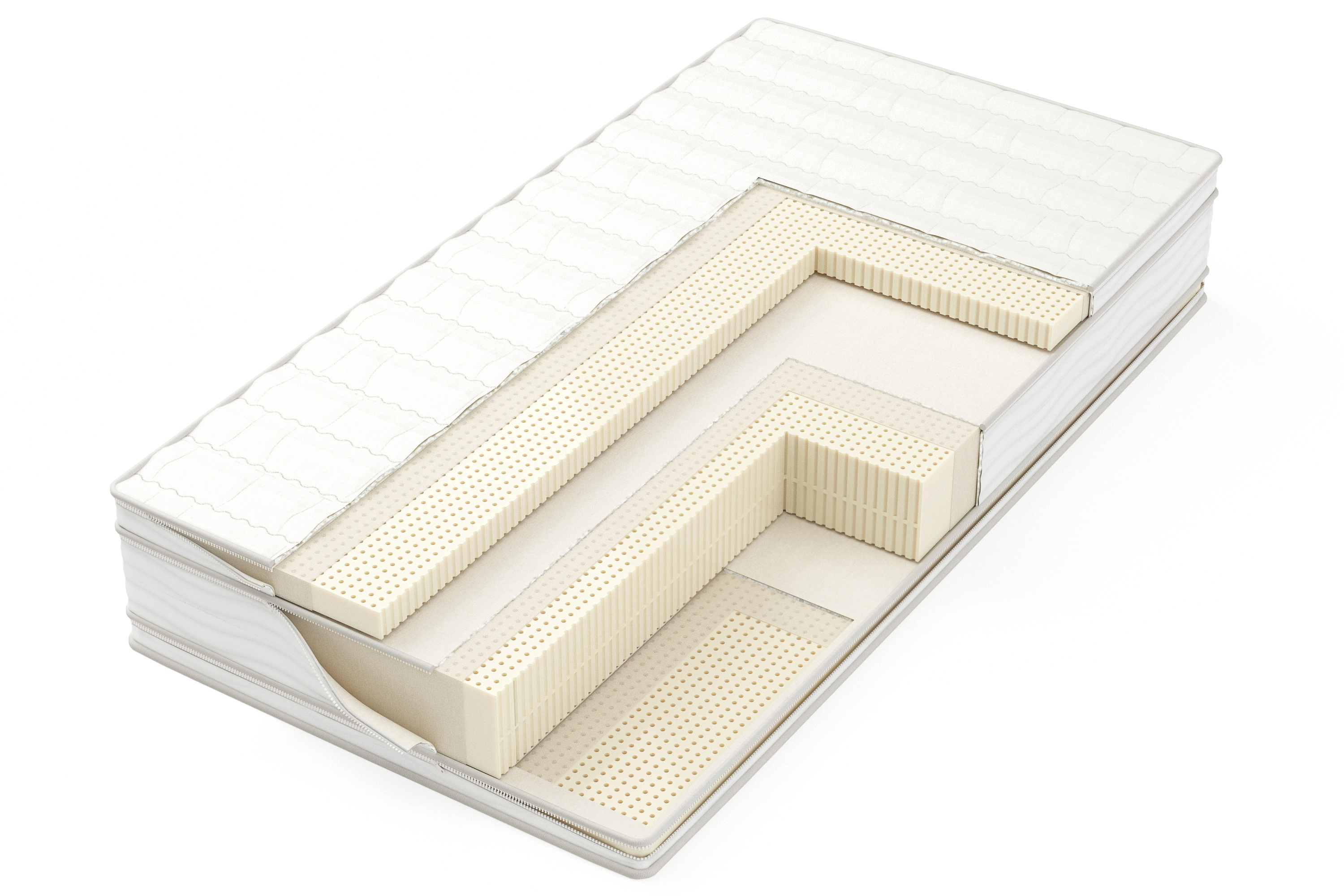

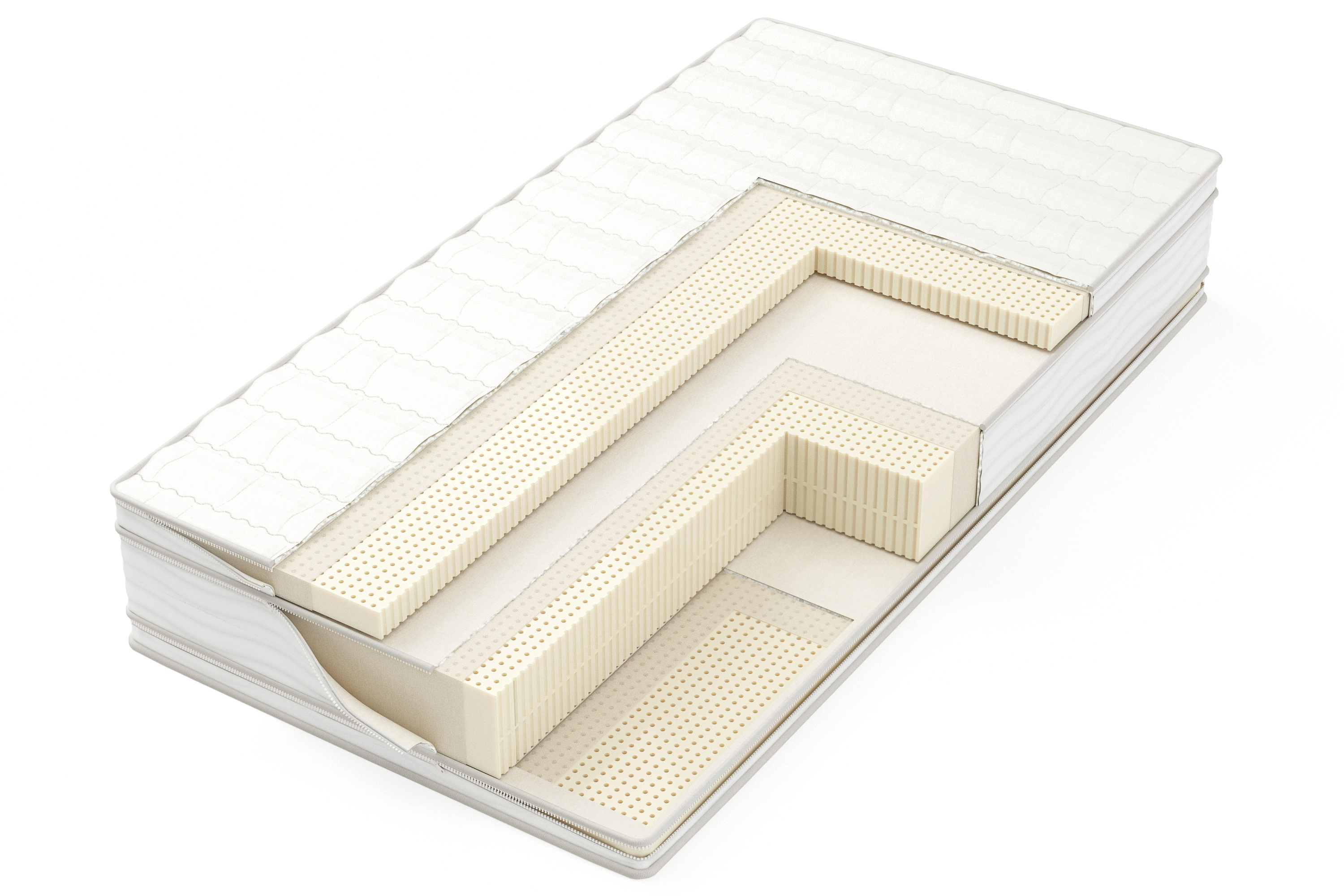

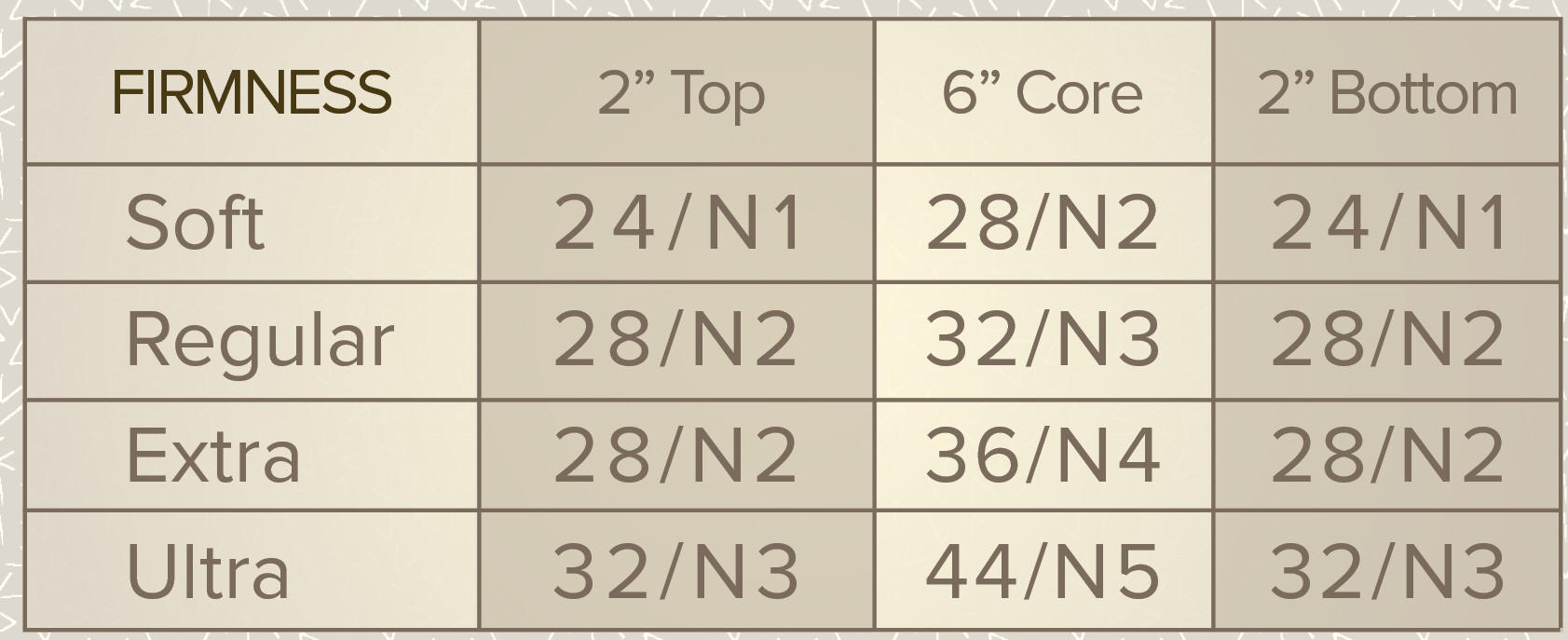

THE ULTIMATE 2" Softer Latex on Top 6" Firmer Latex in Middle 2" Softer Latex on Bottom 3-Chambers 3-Zippers 3-Socks Quilt Top Quilt Bottom Handles |

|

||||||||||||||||||||

| 13. Design | |||||||||||||||||||||

|

We use Organic Cotton Quilting on both top and bottom No Pesticides No Fertilizers |

||||||||||||||||||||

| 14. Cotton (quilting) | |||||||||||||||||||||

We used Certified Organic Wool Quilting on both top and bottom |

|

||||||||||||||||||||

| 15. Wool (quilting) | |||||||||||||||||||||

.jpg) |

All Natural Talalay Latex Top to Bottom No Fillers No Substitutes |

||||||||||||||||||||

| 16. Natural Talalay | |||||||||||||||||||||

|

TOP QUILTING We Quilt both Sides |

||||||||||||||||||||

| 17. Quilt (Bottom) | |||||||||||||||||||||

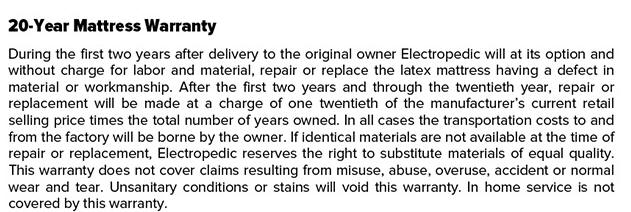

BOTTOM QUILTING We Quilt Both Sides Completely Reversible 20-Year Warranty |

|

||||||||||||||||||||

| 18. Quilt (Top) | |||||||||||||||||||||

and triple stitch around the corners. |

We double stitch around the sides |

||||||||||||||||||||

| 18. Stitch (Sides & Corners) | |||||||||||||||||||||

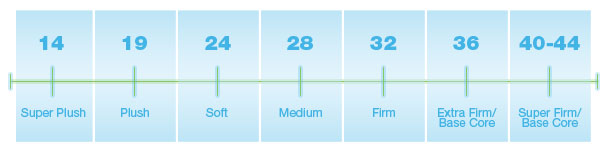

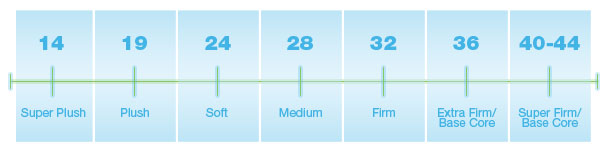

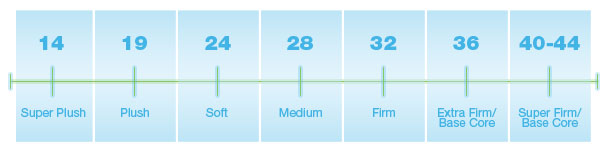

Select the Firmness for the Top 2" of Talalay Latex 19 ILD- Softest 24 ILD - Softer 28 ILD - Soft |

|

||||||||||||||||||||

| 20. 2" Top Layer (Select Firmness) | |||||||||||||||||||||

Topper wrapped in its own Organic Cotton Stock |

.jpg) TOP LAYER ORGANIC COTTON SOCK |

||||||||||||||||||||

| 21. Sock (Top Layer) | |||||||||||||||||||||

Select the Firmness for the Bottom 2" of Talalay Latex on Bottom 19 ILD- Softest 24 ILD - Softer 28 ILD - Soft |

|

||||||||||||||||||||

2" of Softer Latex on Bottom |

|

||||||||||||||||||||

| 22. 2" Bottom Layer (Select Firmness) | |||||||||||||||||||||

Bottom 2" Latex Wrapped in its Own Organic Cotton Sock |

|

||||||||||||||||||||

| 23. Sock (Bottom Layer) | |||||||||||||||||||||

.png) Select the Firmness for your Middle Core 28 ILD - Soft 32 ILD - Regular Firm 36 ILD - Extra Firm 44 ILD - Regular Firm |

|

||||||||||||||||||||

|

6" Talalay Latex Core Available: Soft Regular Firm Extra Firm Ultra Firm |

||||||||||||||||||||

| 24. Core (Select Firmness of Middle 6") | |||||||||||||||||||||

.jpg) Middle Core Hand Wrapped In Its Own Organic Cotton Sock |

.jpg) |

||||||||||||||||||||

| 25. Sock (Core) | |||||||||||||||||||||

|

Top Layer - Own Chamber 3-Separate Layers of Talalay Latex Each Layer in its Own Chamber (Not Glued Together, or "Just Loose") |

.jpg) Separate Chamber between core and topper |

||||||||||||||||||||

| 26. Chamber 1 (between middle core and top layer) | |||||||||||||||||||||

Separate Chamber between core and bottom |

Bottom Layer - Own Chamber 3-Separate Layers of Talalay Latex Each Layer in its Own Chamber (Not Glued Together, or "Just Loose") |

||||||||||||||||||||

| 27. Chamber 2 (between bottom middle core and bottom layer) | |||||||||||||||||||||

.jpg) Separate Zipper for Top Layer |

.jpg) |

||||||||||||||||||||

| 28. Zipper 1 (Top Layer/Sock) | |||||||||||||||||||||

|

.jpg) Separate Zipper for Middle 6" Core |

||||||||||||||||||||

| 29. Zipper 2 (Middle Core/Sock) | |||||||||||||||||||||

|

Separate Zipper Bottom 2" Layer |

|

||||||||||||||||||||

| 30. Zipper 3 (Bottom Layer/Core) | |||||||||||||||||||||

|

Handles Completely Reversible Head to Foot Upside Down |

.jpg) |

||||||||||||||||||||

| 31. Handles | |||||||||||||||||||||

|

|

|||||||||||||||||||||

|

START  FACTORY DIRECT HAND-MADE-ONE-AT-A-TIME WITH LOVE & CRAFTSMANSHIP |

FINISH |

||||||||||||||||||||

| 32. Bravo! THE ULTIMATE | |||||||||||||||||||||

|

Note: The Organic is not available in the Talalay Process   Talalay Latex Mattresses are the #1 Highest Overall Rated Mattress in the Industry

It Doesn’t Off-Gas Talalay doesn’t off-gas like synthetic foam or polyurethane. You may notice the “new bed smell” of the latex when it first arrives, but you can rest assured that no harmful chemicals are being released because Talalay is made of only natural ingredients. Talalay Latex is the #1 Latex Foam in the Industry Compression TestThis test simulates the effect of body impressions on the latex after a person lies on the bed for extended periods of time. Latex mattress samples are compressed to 50% of their original thickness for 22 hours at 158 ° F. When removed, the percent loss in thickness is measured. The greater the loss thickness, the more likely the bed will take a body impression over time—which leaves you sleeping in a hole.

Impact TestThe impact test measures Indentation Load Deflection (ILD), a measure of firmness. The mattress core is ILD tested and then placed into a machine where a weight is dropped on the latex repeatedly for 24 hours. The product is then removed from the machine and allowed to recover for 24 hours. ILD is measured again. The greater the loss in firmness from first measurement to the second means the latex is more likely to breakdown over time. To ensure we produce the most consistent feeling products, Talalay Global ILD tests nine locations on every mattress core. We are the only manufacturer in the industry to do so.

Local Factory | Local Stores | Local Delivery

907 Hollywood Way, Burbank CA 800-233-7382 SERVING ALL AREAS: 800-551-2010

|

|||||||||||||||||||||